Developing Methods

Since the inception of API in 1984, its members have been leaders in advancing state-of-the-art of improvement. This work has been published in two books (The Improvement Guide: A Practical Approach to Enhancing Organizational Performance and Quality Improvement Through Planned Experimentation) and in numerous articles. API continues to work with clients to adapt current methods and develop new ones to increase the rate and impact of improvement. Examples include the Model for Improvement, the Breakthrough Series, and planned experimentation.

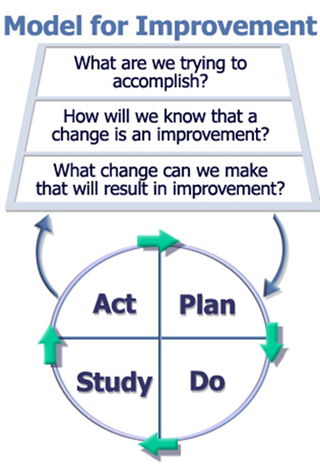

API emphasizes a comprehensive framework for learning and making change within an organization known as the Model for Improvement.

The Breakthrough Series, developed in conjunction with the Institute for Healthcare Improvement (Boston, MA), demonstrates API’s innovative work in accelerating rate of improvement. Although developed for the health care industry, this method has the potential to accelerate the rate of improvement for many industries. It relies on spreading and adapting existing knowledge to multiple similar sites to accomplish a common aim – for example, to reduce employee turnover, reduce cycle times, reduce workers compensation costs, increase voter turnout, or to improve the management of part-time, temporary, and contract employees.

Components of the method can be divided into two segments: pre-work and project work. API’s unique capabilities are important in both segments but are critical in the pre-work segment, when the problem is formulated and the changes are identified and packaged to facilitate adaptation and spread. API works closely with the Chair and Advisory Group, who are the experts in the subject matter, during the pre-work segment.

Planned experimentation can be used to quantify cause-and-effect relationships in complex systems and to test whether changes to products, processes, and services are improvements. The book Quality Improvement Through Planned Experimentation (2012, 3rd edition) provides the information that methodology engineers, as well as those in industry, education, or government need to plan and conduct experiments. As an alternative to the fairly common statistical methods such as standard errors, confidence intervals, and analysis of variance, this book relies on graphical methods to help experimenters ascertain how much the planned changes in the factors are contributing to the variation in the data.